Electric vehicles – leading the way for low-emission mobility

Electric vehicles (EV) are supporting global efforts to tackle climate change by contributing to the reduction of CO2 emissions. According to the Intergovernmental Panel on Climate Change (IPCC), electric vehicles, powered by electricity from renewable energy sources, have the highest climate protection potential and the best eco-balance of all land-based vehicles. For example, up to one million tonnes of CO2 could be saved per year if 10,000 electric trucks were to replace the same number of diesel trucks on the road.

Why electric motors are the foundation of a greener transport transition

Electric vehicles (BEV = Battery Electric Vehicles) rely on electric motors for propulsion, powered by batteries, which in turn are charged by electricity from the grid. These vehicles do not emit any exhaust fumes during operation. This makes them an environmentally friendly mobility alternative, especially when the electricity comes from renewable energy sources – but even with the existing electricity mix, emissions are drastically reduced. This is mainly due to the high efficiency of these vehicles. An electric motor can convert energy into motion with far less loss than a combustion engine. This leads to lower operating costs, as electricity is generally cheaper per kilometer driven than petrol or diesel. In addition, electric drives have fewer moving parts, which results in lower maintenance costs.

Further information on alternative drives and climate-neutral driving can be found on the TRATON site “Alternative fuels and clean driving”.

The challenges of electromobility: charging infrastructure as a key success factor in the transport transition

One of the major challenges facing electric mobility is the charging infrastructure, which has a decisive influence on the range that can be achieved in everyday use. Modern electric trucks can already cover ranges of up to 800 kilometers on a single charge, such as the eTruck from TRATON brand MAN Truck & Bus; the actual range achievable depends on the operating conditions and battery configuration.

Recharging is particularly efficient during mandatory breaks – for example, 45 minutes at lunchtime – with the Megawatt Charging System, which is at least twice as fast in practice as the current CCS2 standard (CCS stands for Combined Charging Standard). For example, the next generation of Scania trucks will be equipped with megawatt charging technology from 2026, enabling a truck to be charged from 20 to 80 percent in less than 30 minutes. This charging time already more than covers the usual requirements of most transport and delivery journeys in accordance with driving and rest times.

In the logistics sector in particular, the success of greener technology is contingent on the development of charging infrastructure. Milence, a joint venture between TRATON, Daimler Truck, and the Volvo Group, serves this purpose and aims to power trucks throughout Europe via a network of at least 1,700 fast-charging stations by 2027. This could motivate more transport companies with fleets travelling throughout Europe to switch to BEV trucks.

The development of new, high-performance traction batteries based on chemistries such as lithium-ion, will also have a major impact on the future of e-mobility. The requirements for commercial vehicles are particularly high in this regard. The weight of the vehicle and the forces acting on the vehicle frame alone mean that the loads on electric trucks are higher than on passenger cars, which requires a much more robust battery design. In addition, the batteries installed in electric trucks have to withstand significantly more charging cycles, as a glance at the average mileage of trucks and passengers cars makes clear: while a truck covers up to 160,000 kilometers per year, a passenger car often only covers a tenth of that.

Investments in battery technology

Manufacturers are rising to the challenge of transitioning to battery-powered trucks by investing in new battery technologies. For example, an assembly plant was opened in Södertälje, Sweden, in 2023 by TRATON brand Scania, which invested 100 million euro in the factory and uses it to assemble batteries for the electric trucks of the future.

MAN is also focusing on in-house battery production. In May 2025, the company began battery production in Nuremberg in a production hall built specifically for this purpose. In the current expansion stage, 50,000 battery packs can be produced there per year, with a maximum capacity of 100,000 units for commercial vehicles.

How digital services optimize the use of electric trucks

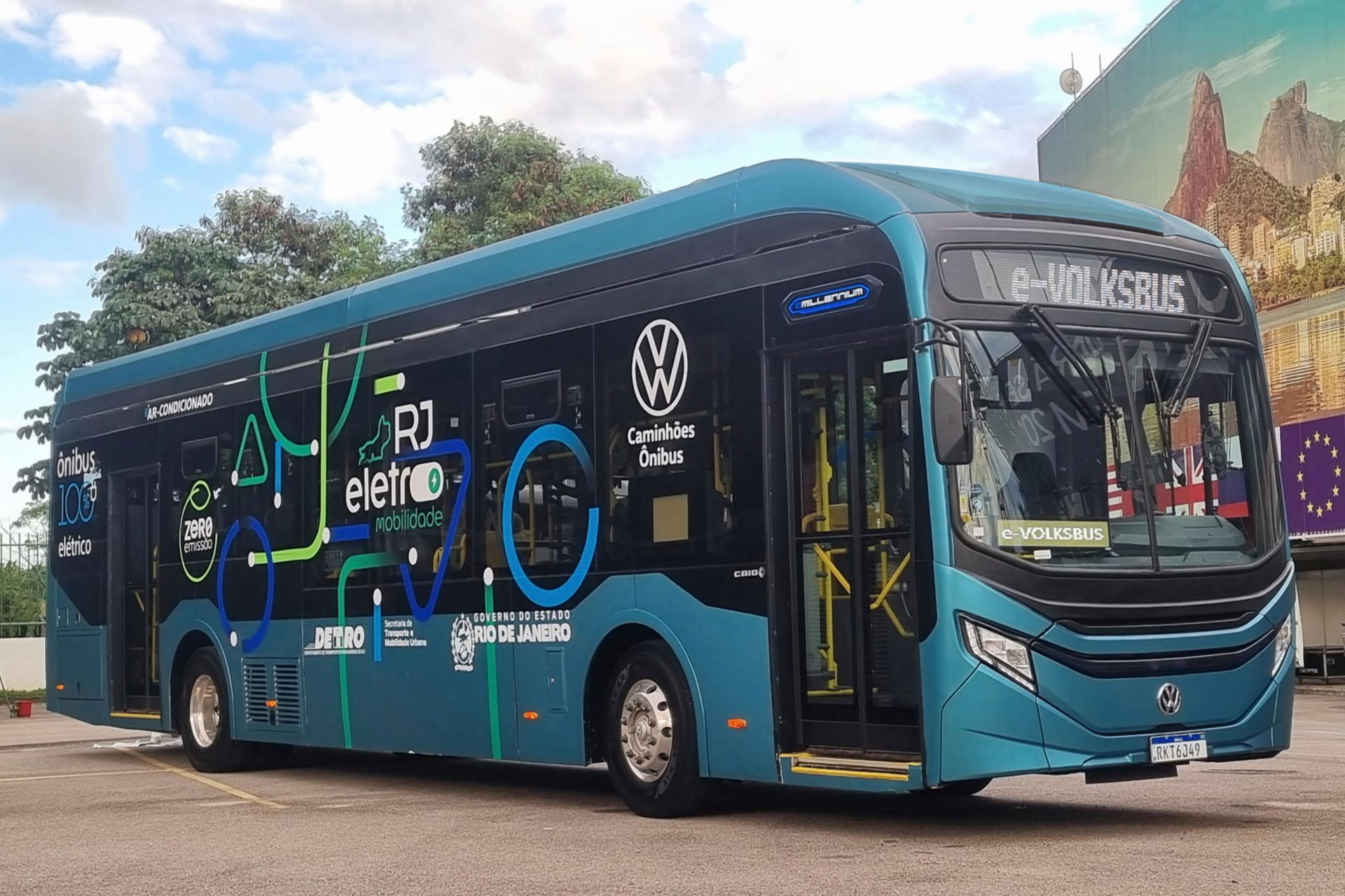

But battery technology is only one aspect of electromobility. MAN has demonstrated how the use of electric trucks can be further optimized through digitalization. The manufacturer, which is one of the leading providers of climate-friendly commercial vehicles, with models such as the Lion's City E electric bus, offers a range of digital services for the MAN eTruck. The MAN eManager program enables comprehensive vehicle and battery monitoring of vehicles during operation. When this is combined with MAN SmartRoute, a control system for drivers and fleet managers, routes can be optimally planned and dangers such as a battery overheating are recognized in good time. In view of the truck charging infrastructure that is still being developed, such systems, which reliably guide the driver to the next charging option and prevent ‘running empty,’ are an important building block for the adoption of the new technologies. The North American TRATON brand International, with its legendary yellow school buses, is also exploring low-carbon mobility – having introduced the first fully electric buses to the road in mid-2021.International is currently working on new solutions and products, amid growing demand for battery electric vehicles and zero-emission transport in the USA. And with the e-Delivery from Volkswagen Truck & Bus, the first electrically powered distribution lorry is in operation in South America, complemented by the e-Volksbus for local public transport.

Driving the industry in the right direction

Electromobility has the potential to transform the logistics industry. It offers clean, efficient, and intelligent mobility that not only contributes to reducing pollution, but also forms the basis for a new, sustainable – and, last but not least, significantly more cost-efficient – transport infrastructure. The challenges along the way are significant, but the advantages and opportunities offered by electromobility make it the indispensable backbone of our future.

.jpg)