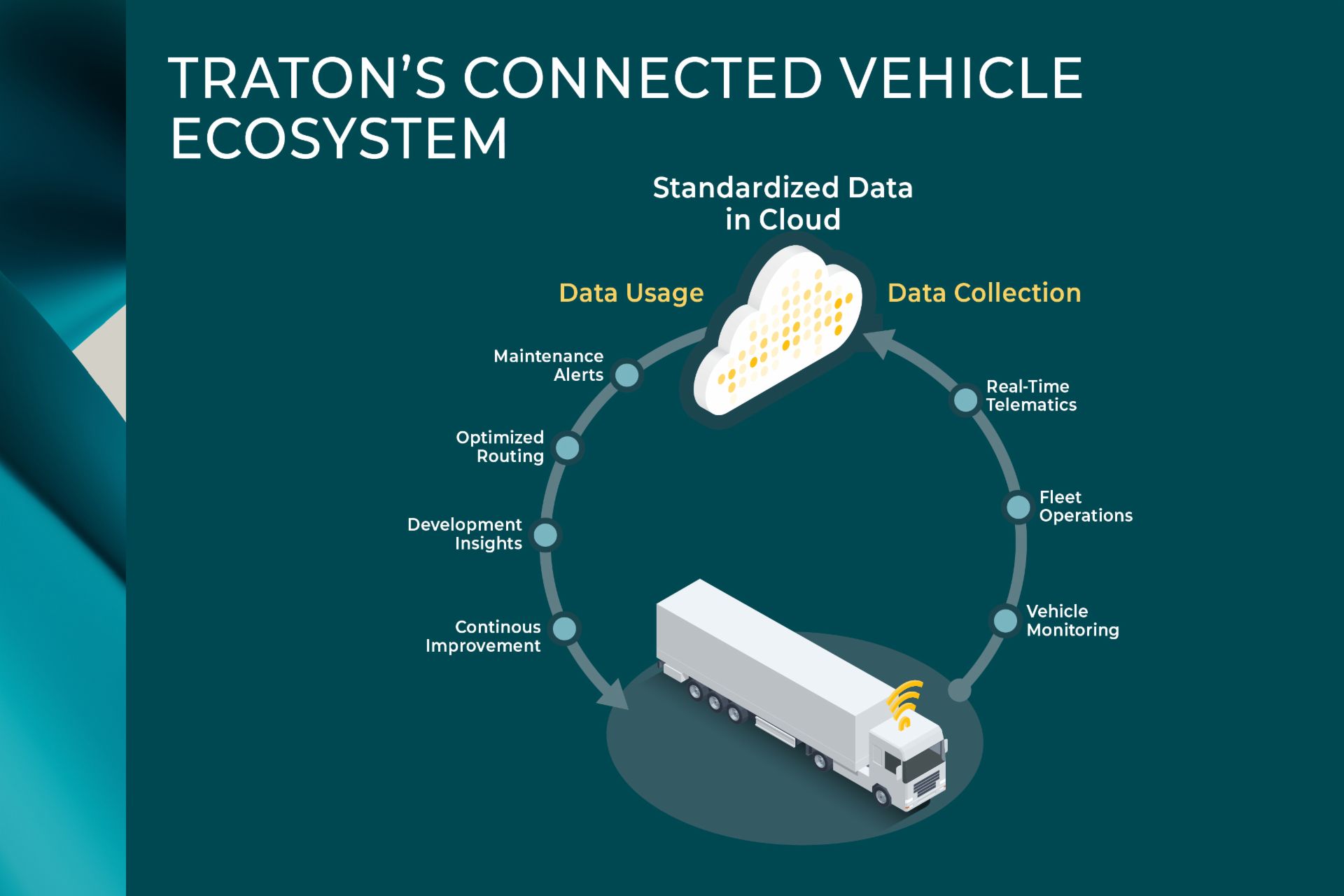

A modern truck continuously collects data about its location, driving behavior, and the functionality of all its components, among other things. The trucks are connected to cloud services, enabling data to be delivered to the customer quickly and seamlessly in real-time. Transportation companies can operate in a data-driven manner, optimizing both their efficiency and safety.

This data has been utilized by TRATON’s brands for several years, both to support their service offerings and in the development of new components.

“We primarily use connectivity to understand how our products behave in operation and to support repair and maintenance processes with insights and information. Connectivity also enables a wide range of digital services that support customers, drivers, and partners within the transportation ecosystem,” says Jonas Jepson, Portfolio Manager Digital Services at TRATON.

Standardization for deeper insights

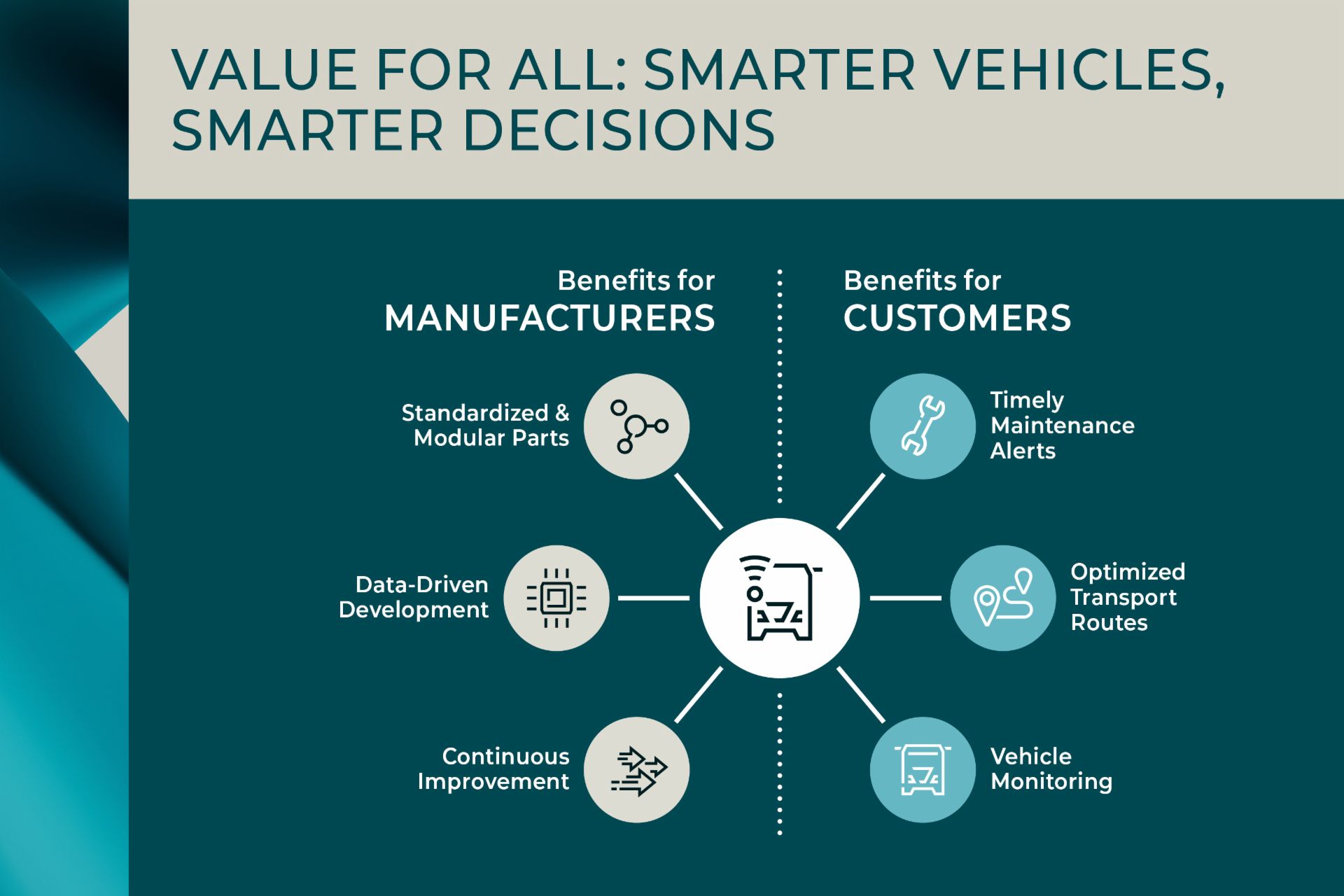

The vast amount of data collected from 1.15 million connected vehicles is, of course, a valuable asset for the TRATON brands – but it has the potential to become even more valuable. Once a standardized way of working is implemented it will function as a modular system for connectivity, and the aggregated data can be utilized by the entire group. More data equates to better data, according to Jepson:

“For example, if you make only two observations, you can’t be certain the data reflects accurate facts. However, with a thousand observations, the reliability increases significantly. With data from a larger sample, you get better facts,” Jepson explains.

He elaborates: “Gathering feedback from a wider global perspective allows for a better understanding of regional variations. For example, a truck that transports sugarcane in South America will age differently than a truck that operates in extreme cold.”

Global data for global improvement

Work is underway to establish a standard for all TRATON vehicles. “In Europe, we follow standards that we are in the process of transferring to China and later North America,” Jepson says.

When the group can work with global data, the ability to produce better components is further enhanced, ultimately leading to even more competitive products. The insights gained from the collected data become valuable in developing standardized and modular parts.

“When we develop a new component, it must be better than the previous one. This improvement is only possible if you know how good the previous one was. You need to know things like when it breaks down and how it breaks down, for example. This experience gathering is crucial to producing better components,” says Jepson.

Leading the way in future transport solutions

TRATON's deep knowledge of today’s transportation landscape allows the group to confidently guide customers toward tomorrow’s transport solutions, such as electric vehicles.

“We excel at developing tools that help customers make the leap from internal combustion engine vehicles to electric vehicles. With data as support, we can see when and how it would be profitable to switch to electric vehicles, the cost of charging, and we have tools to find charging stations, among other things. In new technology areas where customers are inexperienced, we are good at offering expertise and support. And all of this is made possible by using our data,” says Jepson.

As Jepson looks ahead, his vision is as follows: “We aim to create faster feedback loops, better support systems, with the right information at the right time, for all parties in the ecosystem.”

How connected vehicles work

-

The vehicles are equipped with sensors and systems that collect information.

-

Different sensors gather data providing status on the engine, brakes, transmission, tire pressure, fuel consumption, and much more.

-

GPS allows for monitoring the vehicle's position. For example, it enables drivers to receive information on regulations for different areas through geofencing technology as well as generating a driving history.

-

The telematics system collects all data and transmits it to the cloud, making the data available in real-time for all interested stakeholders.

-

The benefits for the customer include the timely detection of service needs and the ability for fleet managers to monitor both their trucks and driver behavior. For manufacturers, this data provides in-depth knowledge about the vehicles that can be incorporated into development work.

-

Did you know? In 2011, Scania became the first truck manufacturer to introduce connectivity as a standard feature in all trucks.

Three Ways TRATON Brands Leverage Vehicle Data

Going electric with the help of data-based analyses

Vehicle data is useful not only for keeping trucks running and monitoring driver behavior, but also for lowering transportation companies’ climate impact.

One example of this is the work Scania did together with the Swedish company Axel Johnson. Scania conducted data-based analyses that showed how Axel Johnson’s transportation flows could be electrified with the greatest possible efficiency. With connectivity and data, Scania secured an optimised transport system with many possibilities, such as digital locks and night-time deliveries.

Accelerating development of autonomous truck by sharing data

The development of autonomous trucks requires a lot of training data, which is used by the algorithms to learn how to steer trucks safely. In 2025, MAN became the first truck manufacturer to publish sensor and driving data from the development of autonomous driving for research purposes. With the data, the developer community can now create better algorithms for highly automated driving.

Data-driven preventive maintenance enhances uptime

Like all TRATON brands, International has utilized vehicle data to develop smart digital services for its customers. A prime example is the International 360 platform, which offers owners and fleet managers data-driven preventive maintenance alerts and up to date status on vehicles in service. One of the many customers who has appreciated this service is Koch Trucking.

“International know exactly what we need so that we are able to customize our technology and the information we need as a company,” said Todd Wright, Director of Maintenance at Koch Trucking.